Investment Casting

Investment Casting is one of the leading technologies which reveals the best quality that the casting industry wants to achieve. Investment Casting is one of the biggest solution sources in various industries to speed up mass production and prototype work. Investment casting is a production method based on pouring molten metal into the mold which is formed by coating the wax model of the designed part with ceramic mud.

Serial production of thin-walled and complex-shaped parts that are difficult and / or sometimes impossible to manufacture with machining methods is possible thanks to Investment Casting.

The production of parts with the Investment Casting method starts with the preparation of the molds for the production of the wax patterns of the part to be produced in the wax injection machines. The molds are made specifically for each part, using high-strength aluminium or steel material.

In the metal molds prepared, manual or semi-automatic wax injection machines press one by one as many as waxes. The machines that are used are capable of 20 - 140 bar pressure, horizontally or vertically, able to press once in every 20 - 80 seconds.

The wax models are melted with either a soldering iron or a similar heater after the visual control and a certain number of waxes are connected to the wax feeders of different sizes, related with the geometrical shape of the part. Wax-assemblied trees are created by gluing the head part to which the casting will be made.

The wax-assemblied trees are covered with ceramic material and the shell. This process is based on dipping the wax-assemblied trees into specially prepared ceramic baths and covering the top of the mud-like ceramic layer with special ceramic sands, sprinkler system or fluidized bed. This process continues until a certain wall thickness is obtained and the desired strength is achieved. After each layer, a certain period of time is waited for drying. In ceramic shell coating, materials such as colloidal silica is used as a binder, alumina and zircon oxide are used as refractories. Ceramic shell coating atmosphere is controlled as 18 - 24 ºC temperature and 45 – 55 % humidity.

After the ceramic shells have dried sufficiently, the clusters are placed in the autoclave to recover the wax inside and the process is completed by keeping the pressure at approximately 6 - 8 bar and the temperature at 200 ºC for 15 - 20 minutes. After wax evacuation process, cracks are checked for ceramic shells and delivered to the casting section.

Ceramic shells are sintered for 1 hour at approximately 1050 - 1100 ºC in order to remove the remaining wax residues and add strength to the ceramic. It removes the risk of cracking due to the temperature difference which will occur during casting of the ceramic shells that gain strength through sintering.

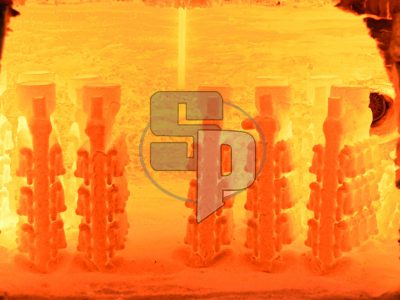

Melting is performed by preparing a recipe that is suitable for the chemical analysis of the material to be casted, by charging the metal to the induction furnace. The casting process is performed after the casting temperature is determined according to the part geometry and material is set. In order to prevent cracking of the ceramic shell and rapid solidification during casting, casting is performed while the ceramic temperature is about 850 ºC - 900 ºC.

Ceramic shells which are left for cooling after casting, are broken by vibration with pneumatic breaker. Rough ceramic cleaning is done in the sandblasting machines and sent to the cutting section.

The parts are cut from their feeders with grinders. In order to get rid of the remaining feeders of the parts, the feeders are cleaned with spiral grinders or horizontal sanding machines depending on the part geometry. After surface control and leveling is applied to the parts, the surface is sandblasted and sent for visual control.

Casted parts are inspected before shipment and the parts that pass the inspection are subjected to destructive and non-destructive inspection methods that are applied according to the measurement control and customer demand. In addition, material compatibility is checked by chemical analysis spectrometry of each casting heat.